Root Density

Increase water, air, and nutrient uptake of grassroots by reducing soil compaction and increasing soil drainage.

Increase water, air, and nutrient uptake of grassroots by reducing soil compaction and increasing soil drainage.

Frequently compacted urban soils cause the majority of sports field problems. Reducing compaction softens the soil to allow air, water and nutrients to get in and out of the soil profile, promote deep turfgrass root systems and add shock-absorption and injury evasion for player falls. Achieving these benefits will reduce a sporting field’s overall pesticide, fertilizer and water needs.

Aeration that opens 8 percent of the soil surface should reduce compaction by 10 to 15 percent. The amount of surface opened depends on aeration depth, equipment and frequency.

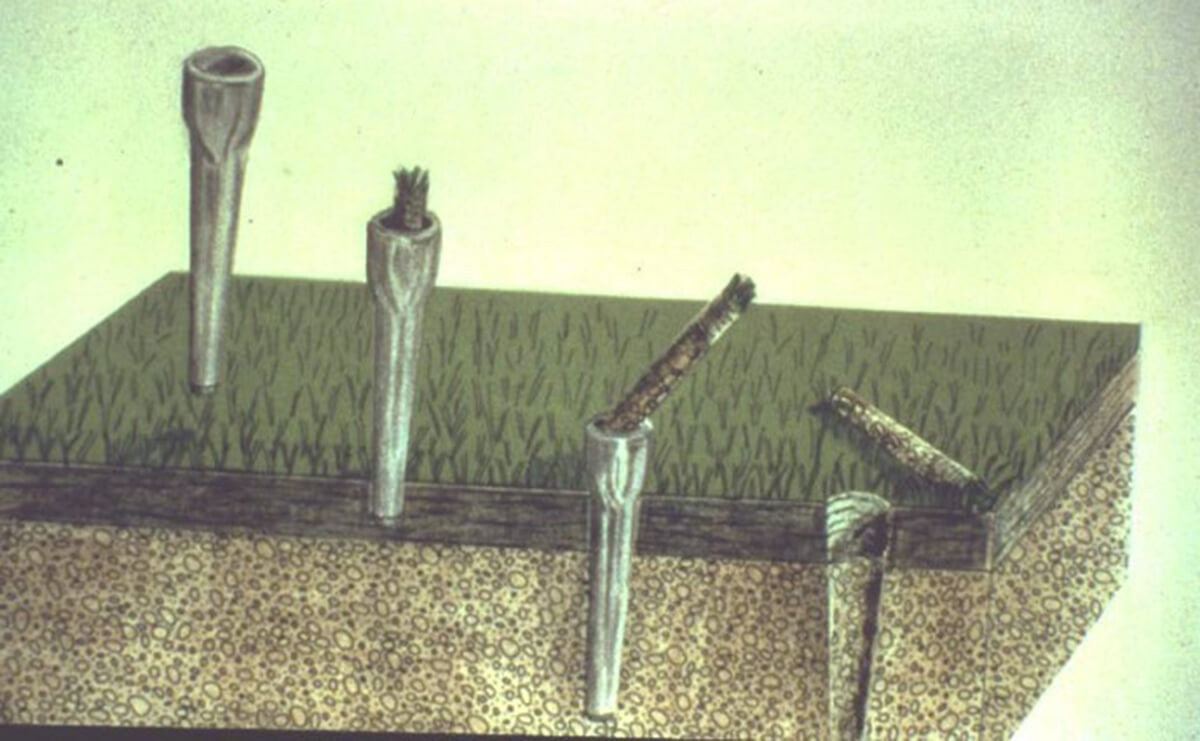

1 to 6” deep→ Known as Surface Aeration, this practice grows strong root mass and microbiology diversity on the top soil layer. Surface aerators use slicers, hollow-tines or solid tines to break the surface.

8 to 12” deep→ Known as decompaction aeration or deep-tine aeration, this practice breaks clay, rocks and construction debris in the soil profile and cuts deep enough in the soil to improve drainage and turfgrass root depth. Most deep-tine aerators use solid tines, but can use hollow-tines.

Slicing→ Slitting the soil three to four inches deep to open the surface for air. This facilitates the lateral growth of Kentucky bluegrass. If densely lined (2” by 2” spacing or closer), can open eight percent of the surface.

Hollow Tine Coring→ Removes soil cores, generally 3-6” deep, to increase soil porosity. The straight up and down action of most hollow tine core aerators open less than one percent of the surface. To increase the amount of surface opened, accommodate the core aeration with a slicer.

Hollow Tine Coring→ Removes soil cores, generally 3-6” deep, to increase soil porosity. The straight up and down action of most hollow tine core aerators open less than one percent of the surface. To increase the amount of surface opened, accommodate the core aeration with a slicer.

Solid Tine Coring→ Uses non-hollow tines to create holes into the soil profile. This equipment can open the surface to air and water, while minimally disturbing fields by not leaving cores on the surface. However, solid tines can increase compaction by pushing soil to the bottom and sides of the cores.

Solid Tine Coring→ Uses non-hollow tines to create holes into the soil profile. This equipment can open the surface to air and water, while minimally disturbing fields by not leaving cores on the surface. However, solid tines can increase compaction by pushing soil to the bottom and sides of the cores.

How often→ High traffic sports fields should receive 6 to 8 aerifications per year. Hollow-tine core for at least two of the aerifications. Slicing can replace hollow tine or solid tine coring for the other aerifications. Managers should aerate fields no less than two times per year.

Where→ To save time and costs, aerate at highly trafficked sections of sports fields as opposed to the entire field. Aerate those sections two or more times to open more of the surface.

When→ Aerate when grass actively grows. Cool-season grasses grow the most in May and September. Aeration greatly complements overseeding, compost topdressing and fertilization by improving seed to soil contact and germination rates.

Park Ridge Park District’s Assistant Superintendent of Buildings & Grounds, Kristi Solberg, utilizes aeration frequently to open up the soil profile and improve drainage.

“Aeration is extremely important, because the soils we have in Park Ridge are very compacted, clay dominant and don’t let any water percolate down,” Solberg explained. “So we are trying to promote that water to drain down into the soil system.”

Solberg oversees a very comprehensive aeration program that uses a hollow tine aerator, a deep tine aerator and a slicer. Of the three machines, Park Ridge uses the slicer around 75 percent more than the other two because it “is quicker, leaves less of an impact and is easy to do year-round.” Meanwhile, the district brings out the hollow tine aerator one to two times per year in the spring and fall. Finally, Park Ridge resorts to the deep tine aerator on rare occasions such as after a large community event when turfgrass wear is extreme.

Since aeration can take significant staff time, Solberg strategically prioritizes high wear zones. “You really want to hit the center of the fields more,” said Solberg. “You don’t have time to hit that whole soccer field four or five times a year like you need to hit the center.”

Consequently, Park Ridge Park District reduces compaction on more fields by concentrating on the wear zones and this results in less weed pressure.

“Natural lawn care is easier than some people might think it would be,” Solberg stated. “It can seem like change is hard, but if you start small, even at one park, that can really get you jump-started in the right direction.”

Well drained fields create a better environment for the grass plant by increasing pore space and reducing nutrient loss. Soil compaction and clay tend to cause low infiltration rates (< 1 inch per hour) in native soil fields that prevent turfgrass seeds from germinating and roots from taking up nutrients. Inexpensive methods to improve drainage include aeration or adding soil amendments. Do not mix sand into clay soil as a substitute.

Poor drainage on some natural fields may warrant a complete design renovation with sand and/or drainage tiles. See Table 1 for field redesign options if your district or authority needs to keep a field in-play after heavy rain events.

Table 1. Overview of field design options to handle heavy rain events. MGG recommends native soil fields over the other options. In the case that drainage is very poor and rain very high, however, MGG will suggest sand-based alternatives.

| Soil | Main Benefit | Construction Cost | Maintenance Cost | Construction Time |

Infiltration Rate |

| Native Soil Field | Low to no cost for construction, can have soft surface for playability | N/A | $4,000-$8,000 in material costs, 250-415 labor hours (dependent on number of games) | N/A | Slow if in Clay |

| Conventional Sand Based Field | Rapid drainage to keep field in-play after heavy rain events. | Installation ranges from $400,000 - $600,000 | $4,000-$8,000 in material costs, 250-415 labor hours (dependent on number of games) | 6 months | Rapid |

| Sand Capped Field | This method is less expensive than the conventional sand based field | Installation ranges from $150,000 - $300,000 | $4,000-$8,000 in material costs, 250-415 labor hours (dependent on number of games) | 6 months | Rapid |

| Sand-Cap Build-Up Field | The field is playable throughout construction and annual maintenance costs decrease significantly | Installation ranges from $58,000 - $103,000 | $4,000-$8,000 in material costs, 250-415 labor hours (dependent on number of games) | 1 month | Rapid |

| Synthetic Field | Handles wear better that turfgrass. | Installation ranges from $600,000 - $1,000,000 | $6,000 per year in material costs, 375 labor hours | 2 months | Rapid |

Harmsen’s home country of The Netherlands prohibits pesticides and herbicides on sports and golf courses. Challenging weather conditions of heavy rainstorms oscillating with longer periods of drought made it hard to grow quality sports fields, conserve water and manage stormwater.

In response to these restrictions and changing weather patterns, Harmsen co-developed the DrainTalent technology to help sports managers maintain high performing fields and communities capture excess water in rain events.

“With DrainTalent, we see the roots grow down in search of water. We can optimize the moisture level 24/7 resulting in healthy and strong plants,” Harmsen explained. “When the grass is healthy and strong, it is less vulnerable to diseases and fungal diseases.”

The DrainTalent technology optimizes moisture in the soil by extracting and storing excess water from the field and bringing the excess water back into the soil during dry conditions. At this time, DrainTalent only works in sandy soils, not high clay soils frequently found in the Midwest, but a clay sublayer is a benefit. Managers considering DrainTalent should investigate options to incorporate sand such as installing a built-up athletic field sand-capped system, Draintalent investigates options for potential clients and provides guidance to local contractors in the construction of these high-quality sustainable sports fields. DrainTalent continually tests their technology in different soils and across various conditions at their Research and Innovation Center in the Netherlands to keep pushing the boundaries of sustainability and performance.

One DrainTalent can be connected to two adjacent fields and the system produces significant savings over time by eliminating the need for additional irrigation equipment and reducing or even eliminating external water usage. The system requires minimal soil construction, reduces overseeding costs and increases playing time on the field, all while capturing storm water and reducing or eliminating chemical interventions.